We, Anniwan, have been proudly distributing Alpha-Cure medium-pressure ultraviolet UV lamps for more than 20 years. Our collaboration and partnership with Alpha-Cure has strengthened us and opened up new possibilities, giving us a broader perspective and ushering in a new era for our company.

Thanks to Shane Atherstone, the Chief Technical Officer of Alpha-Cure Ltd, and his highly competent and experienced team, we have gained expertise in UV technology and enhanced our understanding of manufacturing craftsmanship. As a result, we are able to meet the varied UV application requirements of our clients while delivering excellent services and matched technical support.

Established in 1996, Alpha-Cure is committed to delivering advancements in ultraviolet lamp design and technology for the industry, in partnership with leading system manufacturers worldwide. The dedicated R&D departments of Alpha-Cure continuously develop and introduce new and improved products to Alpha-Cure’s extensive portfolio, ensuring the highest level of customer satisfaction and support.

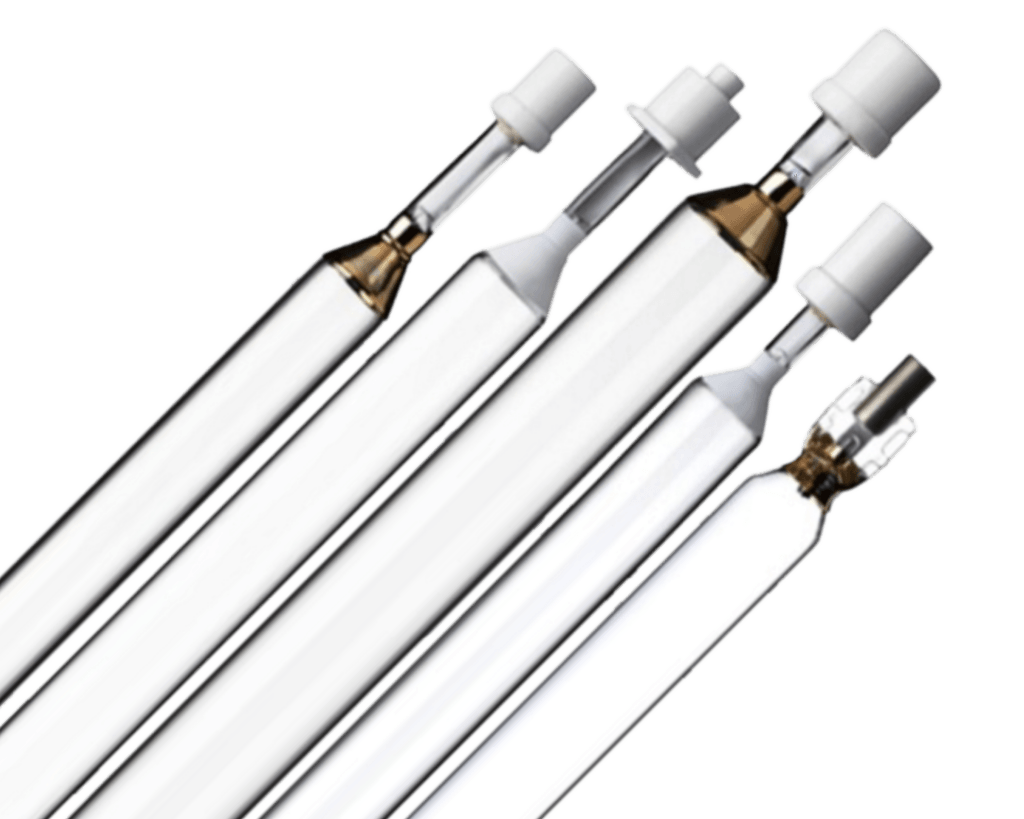

As one of the leading manufacturers of medium-pressure ultraviolet UV lamps, Alpha-Cure provides the most extensive selection of original and replacement UV lamps for various types of systems. The comprehensive cross-referenced database of lamp specifications includes over 20,000 different entries for nearly any curing system worldwide.

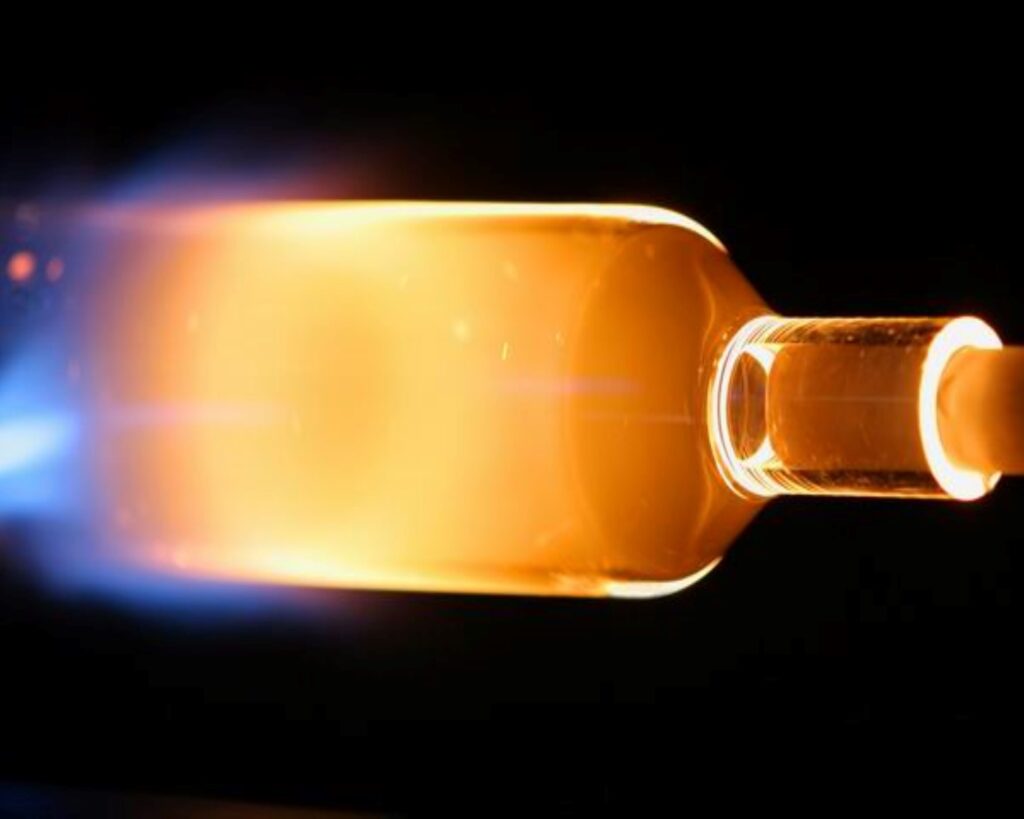

A medium-pressure ultraviolet UV lamp, typically linear in shape, is an electrical arc of light that operates within a sealed environment filled with mercury or additional metal halides. The combination of mercury or supplementary metal halides with the quartz tube itself, when powered by a compatible power supply, can generate radiation output with very distinctive characteristics. This output contains a high concentration of essential ultraviolet spectral energy for various manufacturing processes and industrial applications.

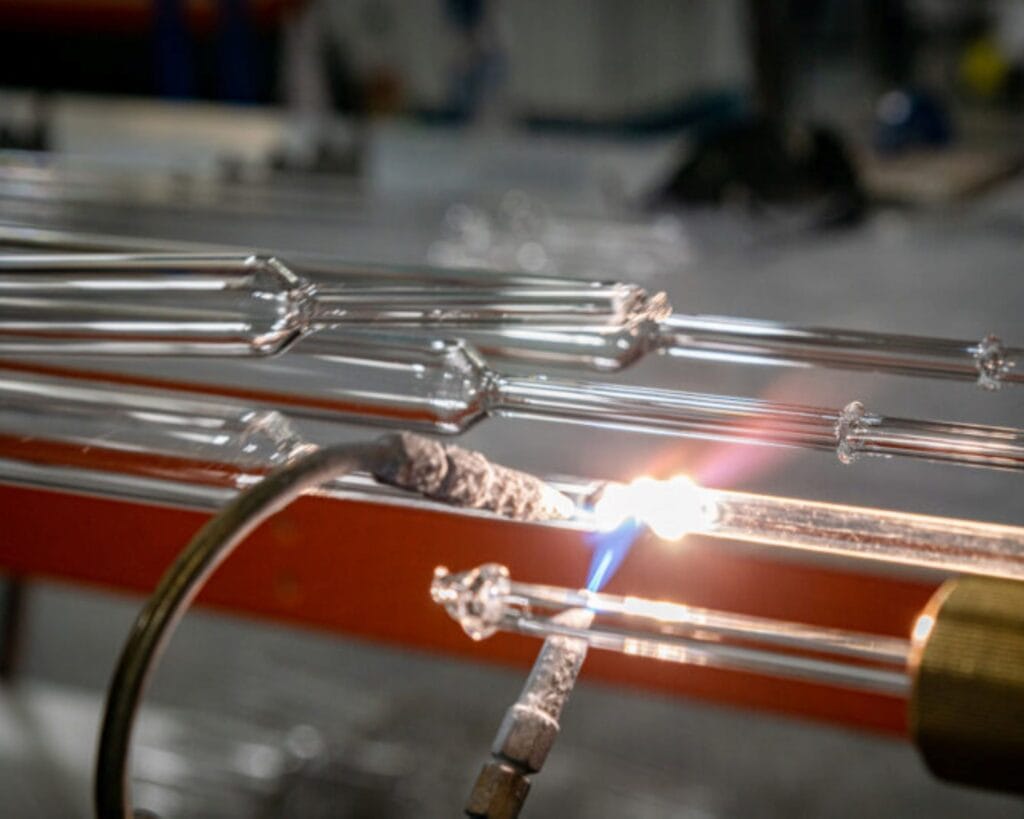

Alpha-Cure is steadfastly committed to using the highest quality materials and production practices. Each component and assembled lamp undergo a rigorous internal inspection and testing process. Only after successfully passing these tests are they used in the production of Alpha-Cure’s high-quality ultraviolet lamps and shipped to customers globally.

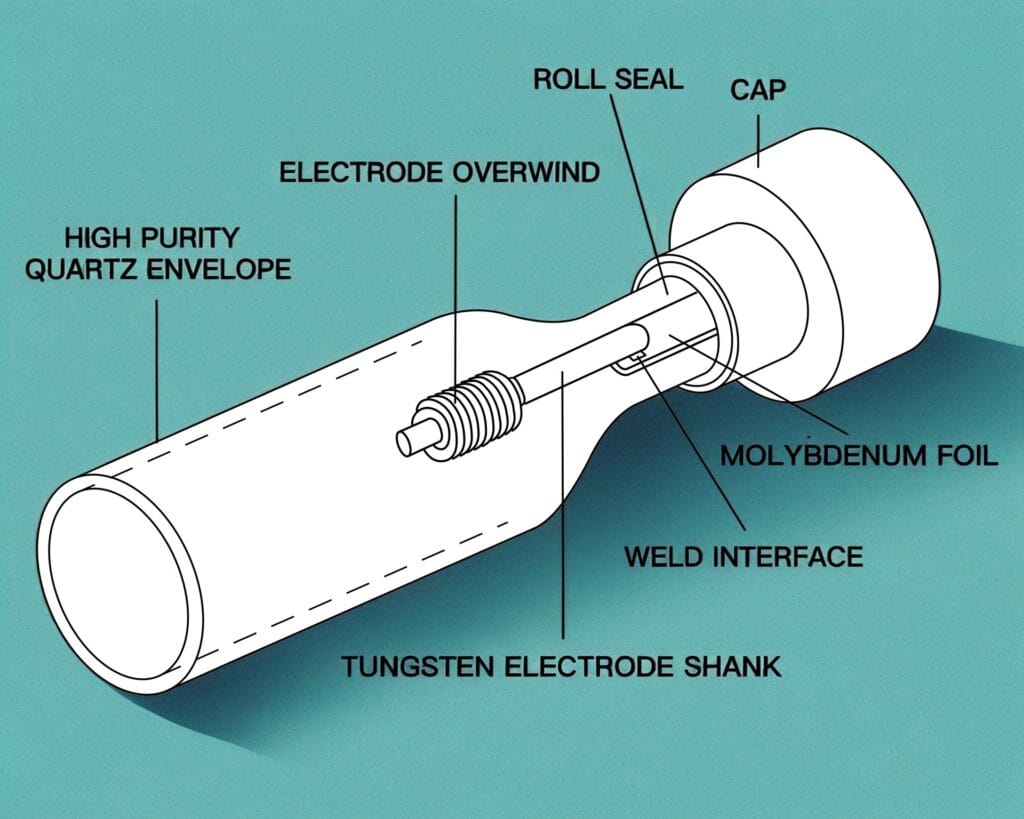

Alpha-Cure’s skilled artisans meticulously transform technically pure amorphous non-crystalline silicon dioxide (quartz) into unique structures. The lamps are designed to accommodate high currents using super-heavy molybdenum foil seals, compressed seals, or double molybdenum foil seals, in order to cater to various high wattages and demanding applications.

The radiation emitted by medium-pressure ultraviolet UV lamps is influenced by several factors. In a gas discharge lamp, the output depends on the gas’s molecular structure, its temperature, the vapor pressure of the gas, and the quality and purity of the materials used in fundamental construction. Alpha-Cure exclusively utilizes top-quality materials, never compromising on substandard options.

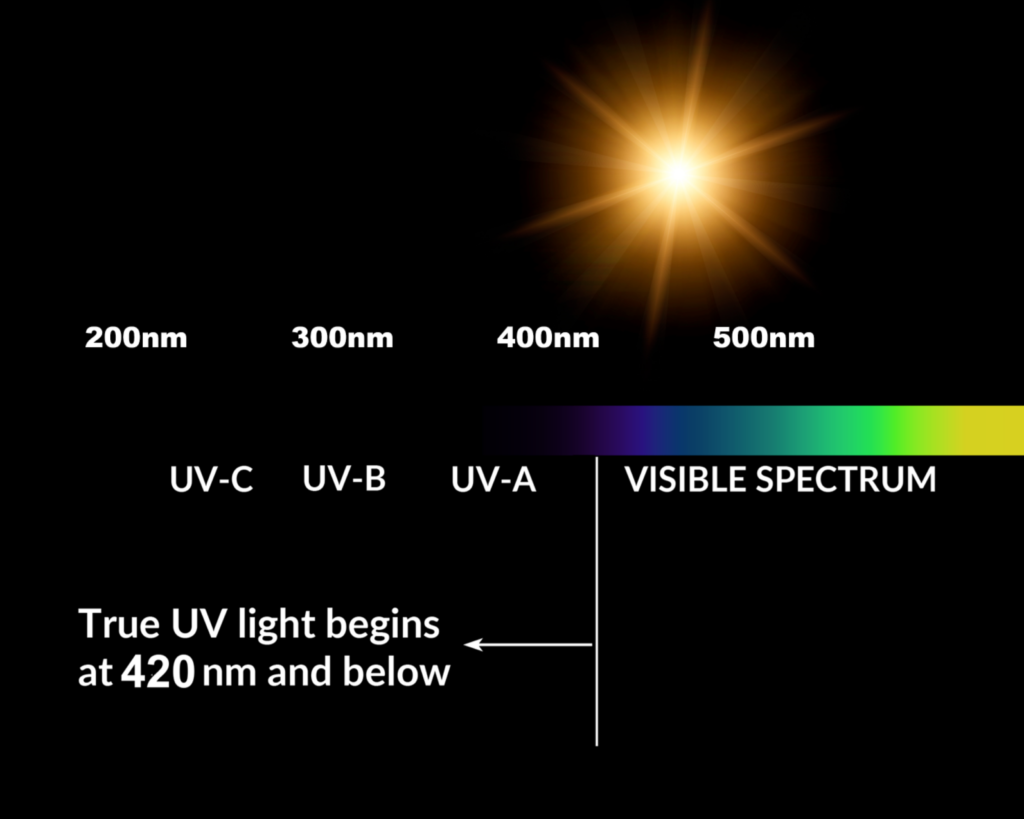

With its unique construction and additive composition, a medium-pressure ultraviolet UV lamp can emit a substantial spectrum of ultraviolet light with specific characteristics, as well as visible light and infrared radiation. This spectrum of radiation creates a highly efficient pathway for applications such as polymerization, halogenation, chlorination, photochemical reactions, UV curing and drying, diazo printing, semiconductor and printed circuit board manufacturing, and the microbial disinfection industry.

Alpha-Cure, with extensive knowledge and experience in the ultraviolet industry, combined with advanced and practical equipment, produces and offers a wide range of ultraviolet spectral products. In addition to standard Mercury, Iron-doped, and Gallium-doped lamps, customized specifications for unique spectra are available.

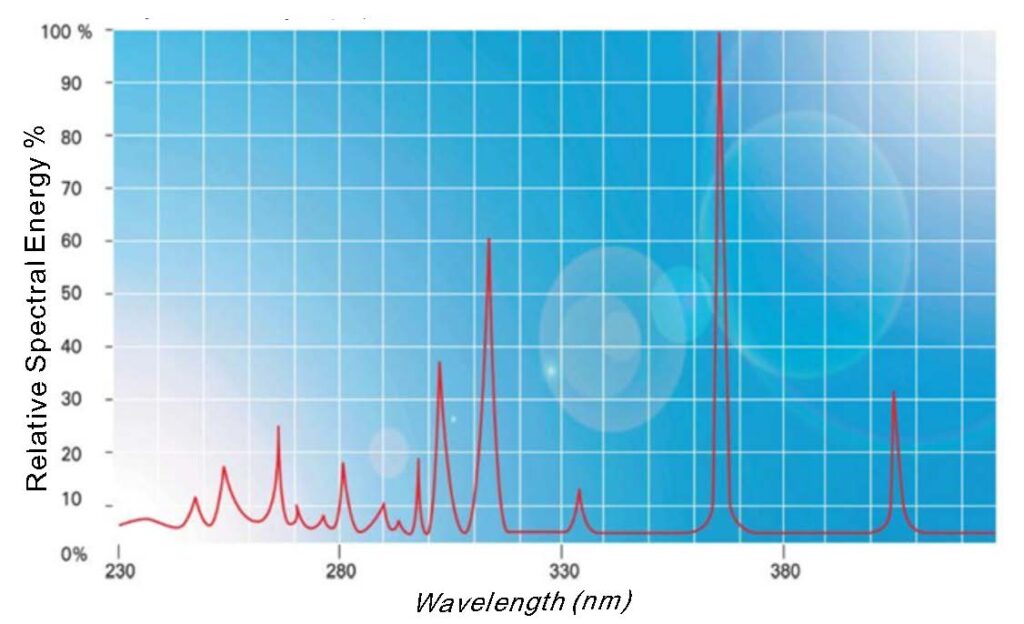

Mercury

The spectral output spans from 200 to 450nm, peaking at 365nm. Notable spectral lines occur at 254nm, 313nm, 405nm, and 436nm. These lamps are utilized in a variety of UV curing processes and for UV sterilization purposes.

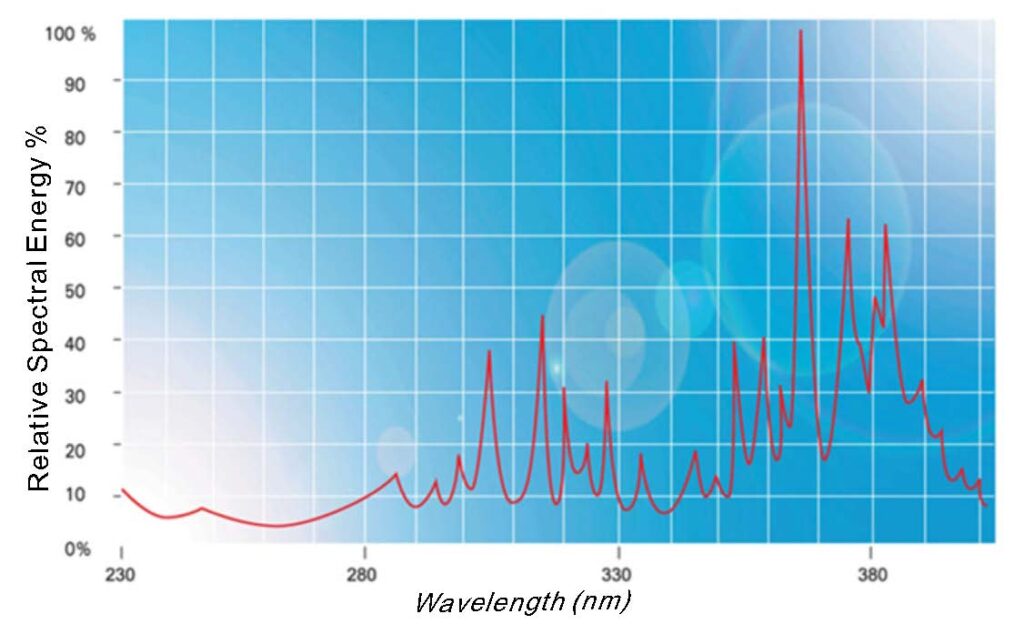

Metal Halide - Iron

This type of lamp is distinguished by a continuous spectrum that spans from 250 to 450nm, with an especially enhanced output in the 380nm region. It is highly effective for use in photopolymer and daylight film exposure systems.

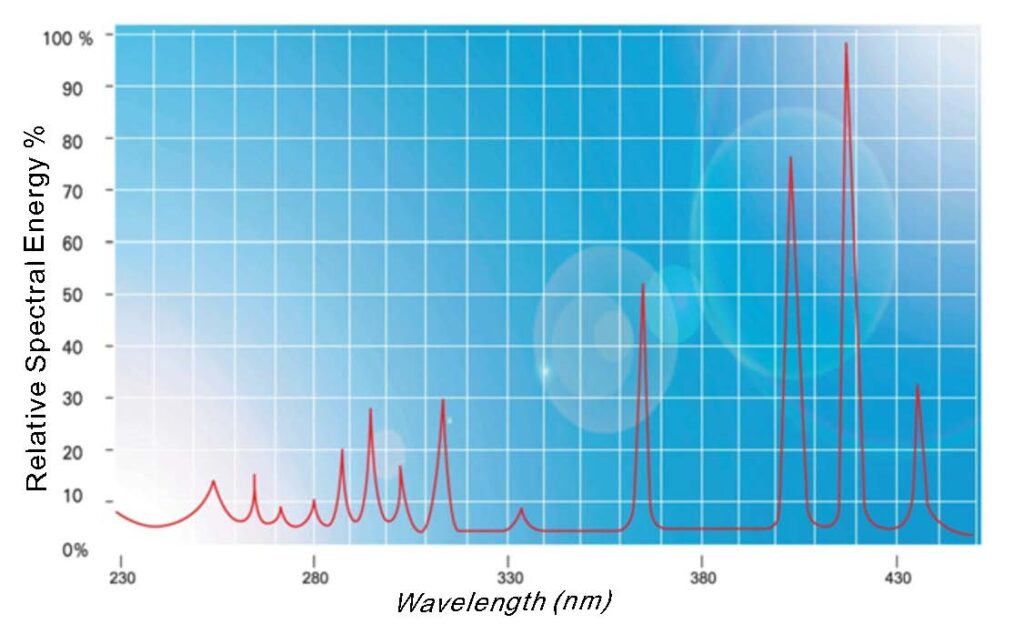

Metal halide - Gallium

The spectral output in the 400nm region is notably enhanced, featuring a peak wavelength at 417nm. This makes such lamps especially beneficial for Diazo-type processes.

Today, Alpha-Cure continues to invest in and consistently improve and refine its technology and craftsmanship. In addition to developing innovative products that meet the increasingly high demands of customers and unique applications, Alpha-Cure is committed to leading the industry in innovation and design.

Are you searching for a lamp? Simply click on the Lamp Request Form button to complete the form and submit your lamp details to us. Our skilled technicians will promptly respond to you.

Looking for a lamp?

Contact with us

Please reach out to us if you have any further questions or specific requirements regarding Alpha-Cure medium-pressure ultraviolet lamps. Our dedicated sales team will contact you shortly.