At our company, we specialize in designing and producing top-of-the-line UV systems that are tailored to meet the unique and specific requirements of each of our valued clients. We pride ourselves on utilizing only the highest quality materials and employing cutting-edge technology to ensure that our clients receive the very best in UV irradiation solutions.

With our forward-thinking mindset, creativity, extensive 20 years of experience in UV technology, and a dedicated team of competent and diligent engineers, our UV systems have received high acclaim for their exceptional performance. We ensure high UV output, perfectly even distribution of UV energy, and maximum cost-effectiveness to meet our clients’ unique requirements.

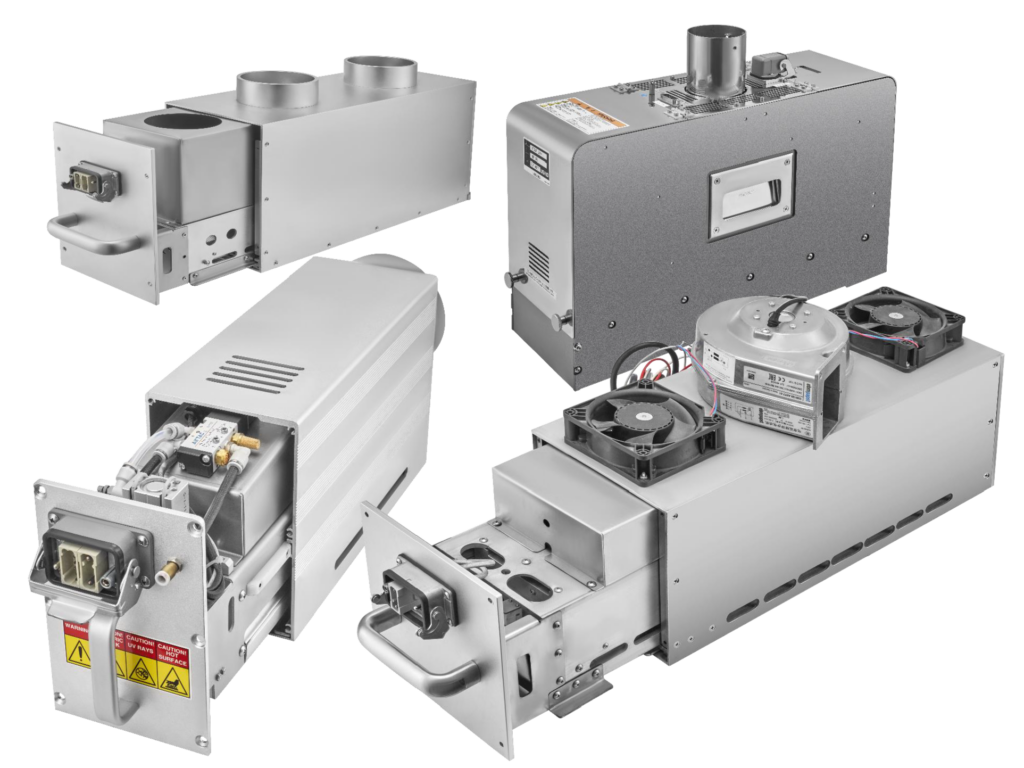

An effective and efficient UV system requires a high-quality irradiation unit that is capable of delivering UV energy to the irradiated surface in a cost-effective and efficient manner. The irradiation unit is a crucial unit of the system, responsible for the proper transmission, reflection, and refraction of the UV radiation. A well-designed and optimized irradiation unit uses reflectors to precisely focus the UV rays in the desired direction, enabling the system to achieve maximum performance.

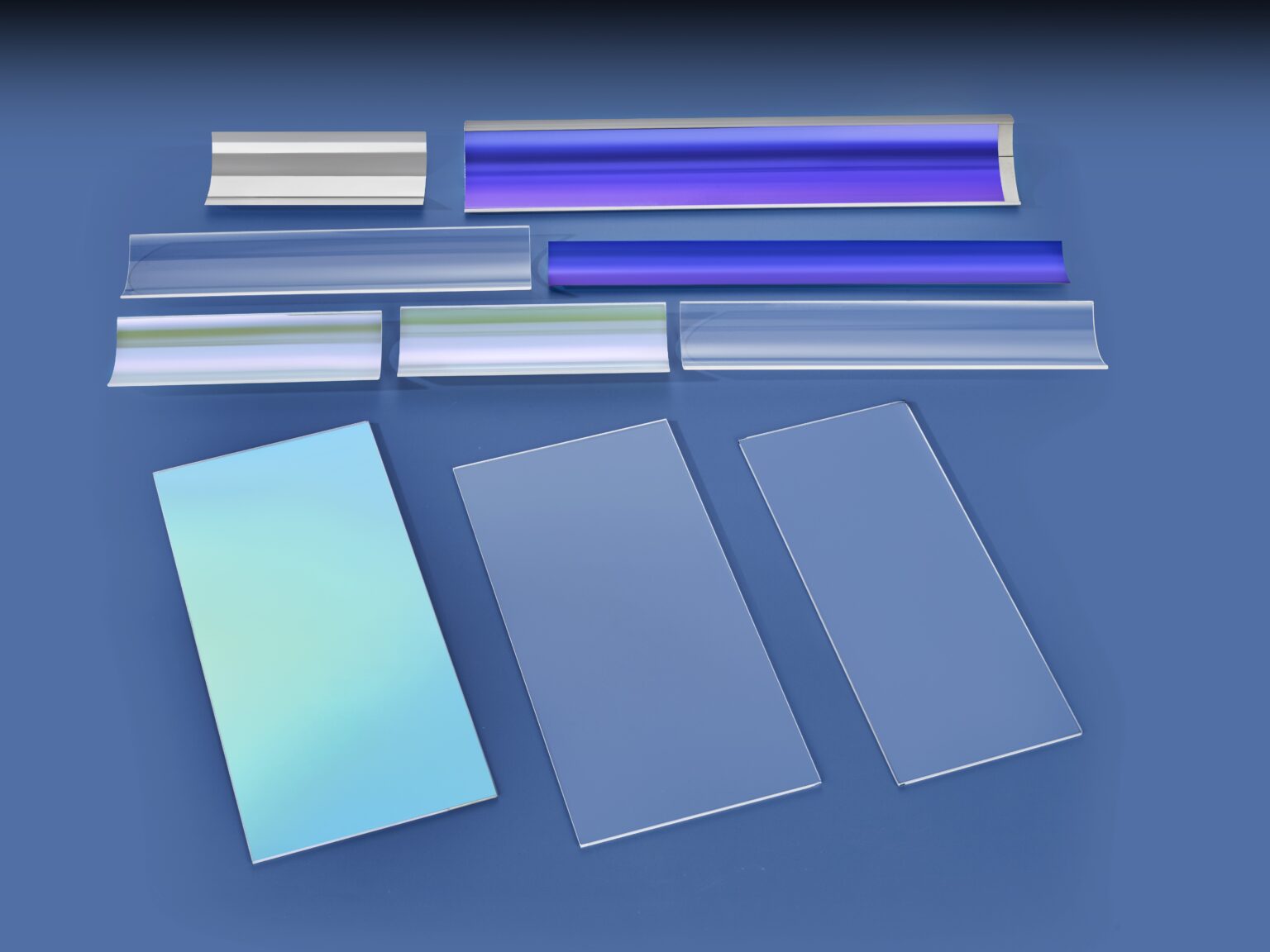

We offer a variety of high-quality and efficient reflectors, including pure aluminum and silver-plated aluminum reflectors, as well as dichroic reflectors such as cold mirrors and cold metal mirrors. To reduce the heat transmitted to irradiated surface and consequently lower the surface temperature, we offer standard quartz plates, and also Infrared Ray Cut Filters to reflect IR while allowing UV to pass through.

The temperature of a UV lamp, when perfectly operating, is best maintained between 600°C and 900°C. At our company, we construct irradiation units with a perfectly matched and paired cooling unit to eliminate excess heat and prevent premature UV lamp failure due to overheating, while keeping the lamp at the optimum temperature. This is essential for prolonging the lamp’s lifespan.

Design & Configuration of reflector types

We utilize the following reflector types and components for constructing our UV systems. Depending on our clients’ needs, other customized reflector types and components are also available.

| Cold mirror | The cold mirror consists of meticulously crafted molded glass substrate, onto which a series of ultra-thin metallic compound coatings are applied. This specialized mirror efficiently reflects ultraviolet light, whereas visible and infrared wavelengths, which are minimally involved in the curing process, are allowed to transmit through the glass. |

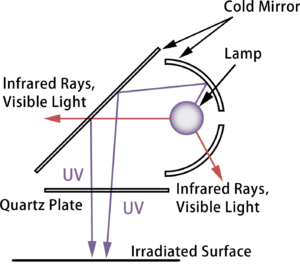

| Dual cold mirrors | This method employs two Cold Mirror components. One features a curved reflective surface designed to deflect ultraviolet light while allowing infrared and visible light to transmit through. The second Cold Mirror has a flat reflective surface that similarly bounces ultraviolet light, while permits the passage of infrared and visible light. |

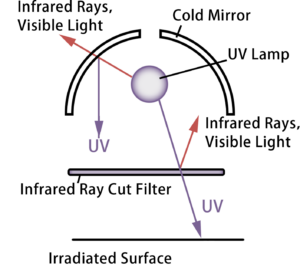

| Infrared ray cut filter | This component is fabricated by applying an advanced coating to a quartz substrate of high purity. This specialized coating is designed to permit the transmission of essential ultraviolet wavelengths, while effectively bouncing visible and infrared rays. |

| Quartz plate | The component is made of pure quartz and is capable of transmitting a broad spectrum that includes ultraviolet light, visible light, and infrared rays. |

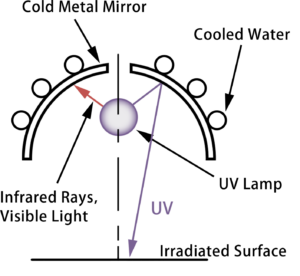

| Cold metal mirror | It is made of multi-layer evaporation deposition on to the metallic reflective surface, enabling it to selectively reflect light within the desired wavelength spectrum while absorbing light in the unwarranted wavelength range. |

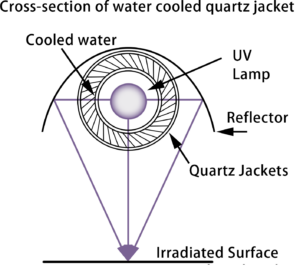

| Water cooled quartz jacket | In this setup, the lamp is housed within a quartz tube, which is then nested inside a larger diameter one. A cooling water system is employed to circulate water between the inner and outer quartz sleeves, effectively dissipating heat and infrared radiation. This process maintains the temperature of the surface being treated at a consistently low level. |

| Aluminum mirror | This reflector is crafted from high-purity aluminum boasting superior reflectance, capable of reflecting a broad spectrum that encompasses ultraviolet wavelengths, visible and infrared rays. |

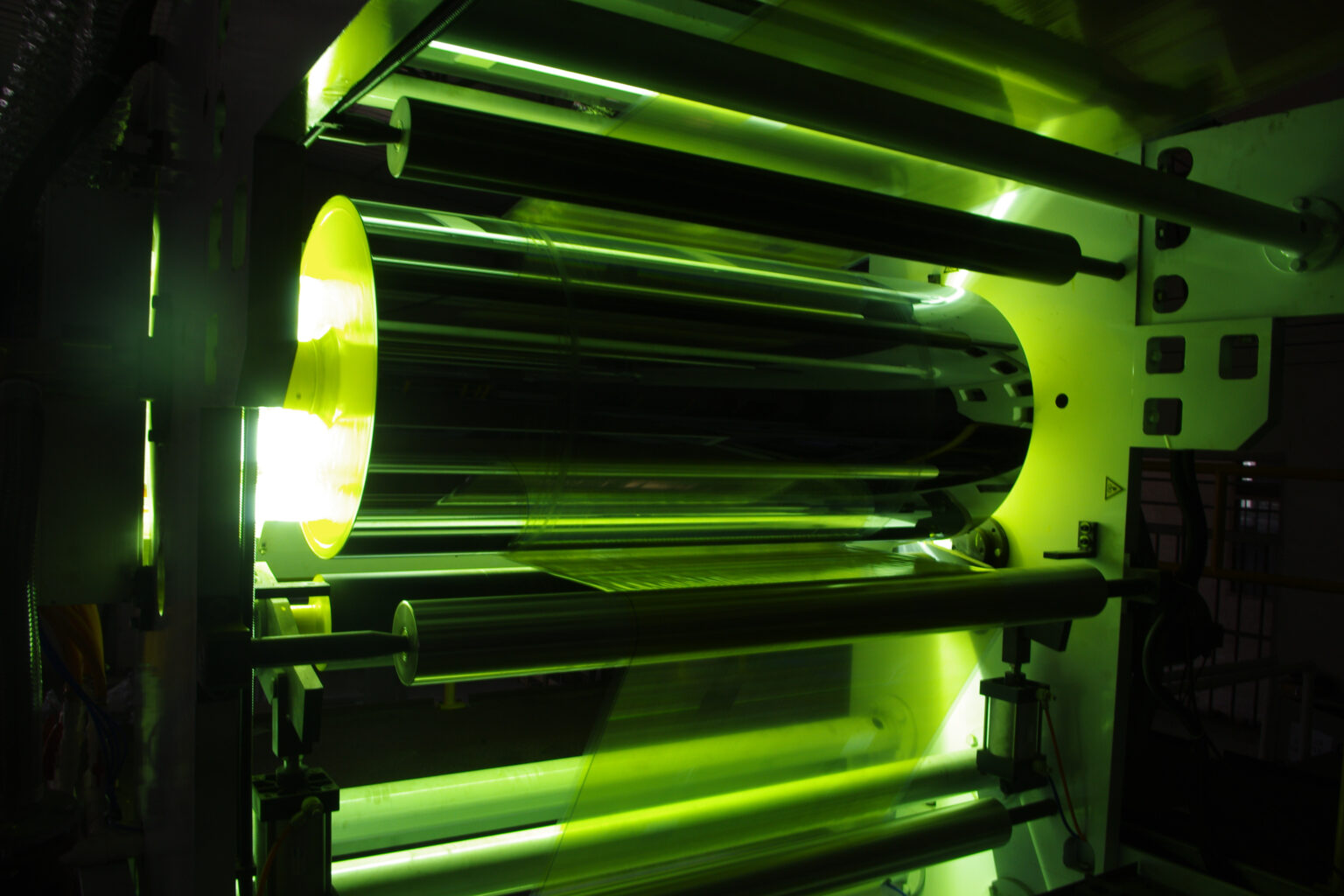

To achieve the highest UV intensity while maintaining the irradiated surface at an ideal temperature, we provide a variety of layout and configuration options as illustrated below.

Dual cold mirrors

The dual cold mirror type employs a curved cold mirror reflector and a flat cold mirror that both reflect ultraviolet rays (UV) while allowing infrared rays (IR) and visible light to pass through, thereby reducing IR exposure to the irradiated surface. This combination is particularly well-suited for low-temperature processes.

Cold mirror & infrared ray cut filter

The cold mirror reflects ultraviolet rays (UV) but transmits infrared rays (IR) and visible light. However, the infrared ray cut filter below the lamp allows UV to transmit while bouncing IR back. In this way, the two components work efficiently together to minimise IR exposure to the irradiated surface.

Cold metal mirror

The cold metal mirror selectively reflects ultraviolet rays (UV) within the desired wavelength spectrum while absorbing light in the unwanted wavelength range. When paired with a water cooling system, heat and infrared radiation are effectively dissipated, thereby keeping the treated surface at a low temperature.

Water cooled quartz jacket

In this setup, a UV lamp is placed inside a quartz sleeve, which is then positioned within another quartz sleeve with a larger diameter. Chilled water circulates between the inner and outer sleeves to dissipate the heat and infrared radiation from the UV lamp. As a result, the amount of infrared radiation reaching the surface being treated is considerably reduced, enabling the temperature to be kept at a lower level.

We proceed to conduct tests and experiments in-house to determine the relative temperature of different combinations of reflector types.

| Reflector + α | Relative temperature (%) |

|---|---|

| Aluminum | 100 |

| Cold mirror | 75 |

| Cold metal mirror | 75 |

| Aluminum + Infrared ray cut filter | 55 |

| Cold mirror + Quartz thermal insulation plate | 50 |

| Cold mirror + Infrared ray cut filter | 40 |

| Water cooled quartz jackets | 35 |

| Dual cold mirrors | 30 |

The requirements of each client for ultraviolet spectral output vary. Additionally, different irradiated substances have varying sensitivities to temperature. Therefore, a well-built UV system, which includes an irradiance unit with a reflector, a cooling unit, a UV lamp with a matched power supply, and optionally a conveyor, could be complex when considering the irradiance angle and distance to address the increase in temperature on the irradiated surface.

We meticulously design our UV systems customized to meet our clients’ specific needs through extensive and consistent testing before delivery, ensuring that both the ultraviolet spectral output and the temperature of the irradiated surface are within the optimal range.